How Suppliers Can Optimize Product Content Syndication to Build Strong Supply Chain Partnerships

If you’re a supplier, getting your product content simultaneously accepted by multiple channel partners without a glitch can seem aspirational. This is because the challenges you face in exchanging and distributing accurate product information often stem from a combination of factors. These include diverse data sources, manual processes, lack of standardization, regulatory complexities, and technological limitations.

However, overcoming these syndication challenges requires more than just recognizing the issues. It calls for better product content management and strategic approaches to collaboration and communication with your supply chain partners.

Now, let’s take a closer look at the root causes of these problems. By doing so, we can shed light on how to optimize your product content syndication process and, in turn, keep your network of partners happy. Providing them with the standardized product content they need is key to success.

What’s Product Content Syndication:

Product content syndication is the process of distributing and sharing product information, such as descriptions, images, and specifications, across multiple platforms and retailer sites. This strategy ensures consistency, accuracy, and broader visibility of product data across the digital ecosystem.

Understanding the Complexity and Challenges of Product Content Syndication

It’s essential to appreciate the complexity of product content syndication for a supplier. This process involves managing a vast array of products, each with its unique attributes, descriptions, images, pricing, and specifications. When distributing this product information manually across various channels, errors and inconsistencies are likely to occur. These issues can lead to delays, which in turn hamper customer experiences.

Additionally, such problems can potentially degrade the entire supply chain’s reputation, especially on major e-commerce platforms like Amazon, Walmart, Grainger, and eBay. Therefore, it is crucial to streamline and automate this process to avoid negative consequences.ay, etc.

Here Are 5 Main Challenges Suppliers Face:

Data Accuracy and Consistency

Suppliers often deal with vast amounts of product data. This data is typically stored in various formats and structures. As a result, maintaining accuracy and consistency across different partner channels can be daunting. Any discrepancy in product information can have significant consequences. For instance, it can lead to customer dissatisfaction. Ultimately, this can result in reduced sales.

Product Data Integration Issues

The inability to integrate product data from internal systems to external partner platforms seamlessly is a common pain point for suppliers. This challenge arises due to incompatibility between different systems, formats, and protocols. As a result, data integration issues often emerge. Consequently, these problems lead to delays and errors in product listings, causing further disruptions.

Customizing Content for Different Platforms

Each partner channel has specific requirements for product listings, including image dimensions, word limits for product descriptions, and details of attributes. Suppliers must customize their product content according to these requirements, which can be time-consuming, labor-intensive, and costly to execute.

Timely Updates and Inventory Management

Keeping product information updated in real-time, especially regarding inventory levels and stock availability, is essential. Failure to provide accurate information can lead to overselling, order cancellations, and damaged relationships with channel partners.

Compliance and Regulatory Issues

Different regions and retail platforms enforce varying regulations and compliance standards related to product information, which are subject to frequent changes. Suppliers must ensure that their product data always complies with regulations to avoid legal complications and penalties.

Overcoming Product Content Syndication Challenges – The Modern PIM Solution

A unified Product Information Management (PIM) system is pivotal for suppliers looking to improve their product content syndication process. Your PIM will be the hub from where you can easily manage and enrich all your product content, before efficiently distributing it across multiple supply chain partner channels.

Here’s How PIM Helps Suppliers Win Complex Syndication Battles:

Centralized Product Content Repository

A PIM system serves as a single source of truth for all product-related data and information. Suppliers can store detailed and standardized product content, including images, descriptions, specifications, and pricing, in one unified repository. This centralized approach ensures data consistency, so it’s far easier to run smooth processes with various partner platforms.

Data Standardization and Enrichment

PIM allows suppliers to standardize product data according to industry norms and partner channel requirements. Additionally, suppliers can enrich their product information by adding attributes, translations, and multimedia elements. Consistent and enriched product data enhances the quality of listings, making products more appealing to potential customers.

Content Customization and Data Transformation

Customize product information and transform raw data for different partner channels effortlessly with a PIM. By storing structured data in the PIM system, suppliers can create tailored product listings for individual partner platforms without altering the original data. This customization ensures that product content meets the specific requirements of each partner, resulting in easy product content syndication.

Accurate Real-time Product Updates

Composable PIM architecture integrates seamlessly with internal systems (ERP, CMS) and external partner platforms through APIs. This integration allows for real-time updates, ensuring that product information, including inventory levels and pricing, always remains accurate across all partner channels. Real-time synchronization features also minimize the risk of overselling, cancellations, and dissatisfied customers.

Workflow Management and Partner Collaboration

PIM facilitates unrestricted workflow management by allowing multiple team members, within or outside an organization, to collaborate simultaneously on product content. Suppliers can set up approval workflows, ensuring that information is reviewed and verified before being syndicated. Collaboration features boost cross-team communication and coordination, leading to more effective product data management.

Robust Data Governance and Compliance

Define validation rules within the PIM system to ensure that all product content adheres to legal requirements and industry guidelines. By enabling the PIM to maintain stringent data governance and compliance standards, suppliers reduce the risk of legal challenges related to inaccurate, misleading, or incomplete product information.

How Unified PIM Strengthens Supply Chain Partner Relationships

Implementing a trustworthy PIM system streamlines business operations and plays a crucial role in developing strong and mutually beneficial relationships with your supply chain partners.

Here Are 5 reasons Why Suppliers and Their Channel Partners Should Use PIM:

Consistently Sharing Accurate Product Content

PIM ensures that product data shared with channel partners is consistent and accurate. By providing partners with reliable information, suppliers build trust and credibility. Channel partners can confidently display accurate product listings, leading to better customer experiences and increased sales.

Greater Collaboration and Communication with Partners

Suppliers can exchange product updates, promotions, marketing materials, and much more, directly through the PIM system. This collaborative ecosystem means that channel partners are well-informed about the latest products and marketing initiatives, allowing them to align targeted strategies with the supplier’s offerings.

Streamlined Product Data Onboarding Process

When suppliers onboard new channel partners, they need to provide them with extensive product data, which is a tedious process. PIM simplifies this by offering a common platform where new partners can access comprehensive and up-to-date product information. This streamlined onboarding process saves time for both suppliers and partners, fostering positive relationships right from the beginning.

Performance Monitoring and Support

A capable PIM comes with analytics and reporting features that allow suppliers to monitor the performance of their product content across all partner platforms. With AI-powered sales and customer behavior data analysis, suppliers can identify popular products and work with partners to optimize strategies and inventory management. Teamwork based on data-driven insights strengthens the supplier-partner relationship.

Quick Responses to New and Emerging Market Trends

Market landscapes are ever-changing, with new trends and customer preferences emerging constantly. PIM enables suppliers to swiftly update product information, launch new products, or modify existing offerings in response to market trends. This agility in adapting to market demands enhances the supplier’s reputation among partners, positioning them as reliable and responsive collaborators.

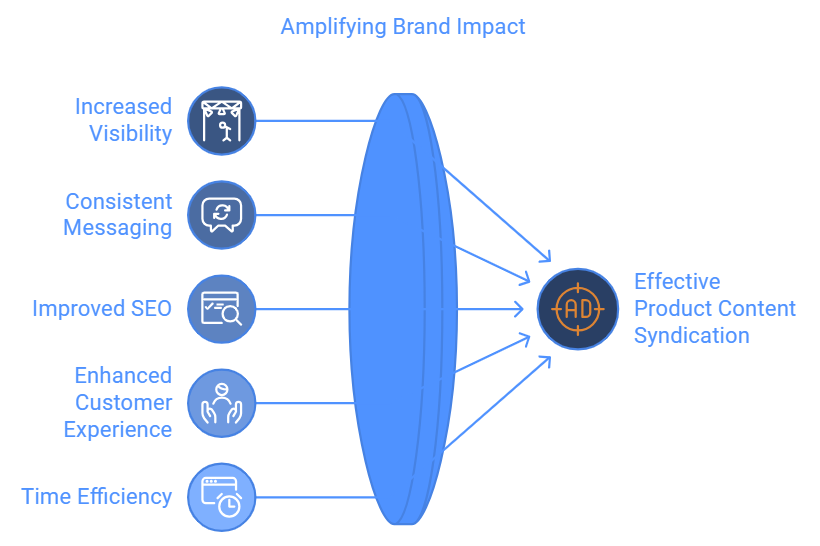

Discover Flawless Product Content Syndication with Bluemeteor

The main goal of using a PIM system is to achieve mutual success in ultra-competitive online and offline retail environments. When suppliers and their channel partners collaborate efficiently, provide accurate and tailored product content, and engage in transparent communication, they are far better equipped to meet customer needs. This customer satisfaction leads to increased sales, positive brand reputation, and overall success for all parties involved.

Bluemeteor Product Content Cloud is a catalyst for improving product content syndication between suppliers and their channel partners. Our solution creates a solid foundation for enduring business relationships. This is how we empower entire supply chains with product content syndication to one of the world’s leading e-commerce marketplaces – Grainger.com

Related Articles

Recent Post

Categories